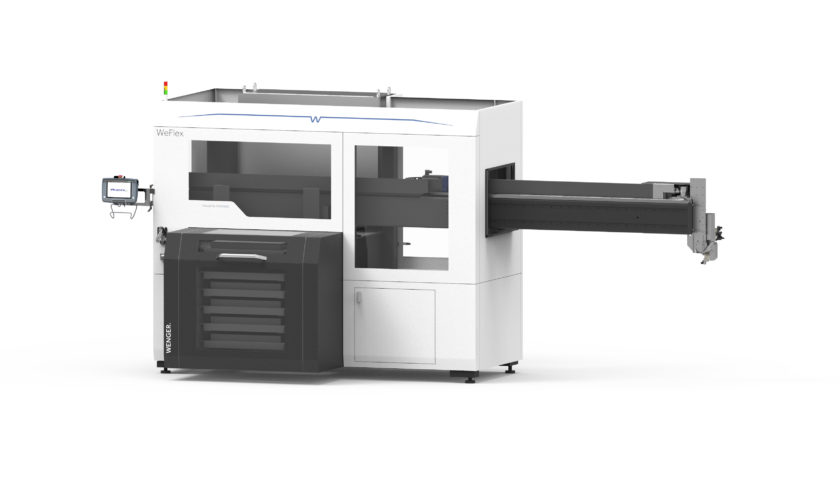

Flexibility is key – as you probably don’t know right now which parts you’ll need to machine in the future. With the WeFlex, you don’t need to. The interchangeable gripper heads allow changeovers between shaft and chuck parts in no time.

Further benefits of WeFlex:

- Image-based setup wizard to save time and avoid incorrect settings

- Ready to integrate pre- and post-process stations

- Energy monitoring and optimisation

- Industry 4.0-ready thanks to standard operating and process data logging

- Intuitive operation

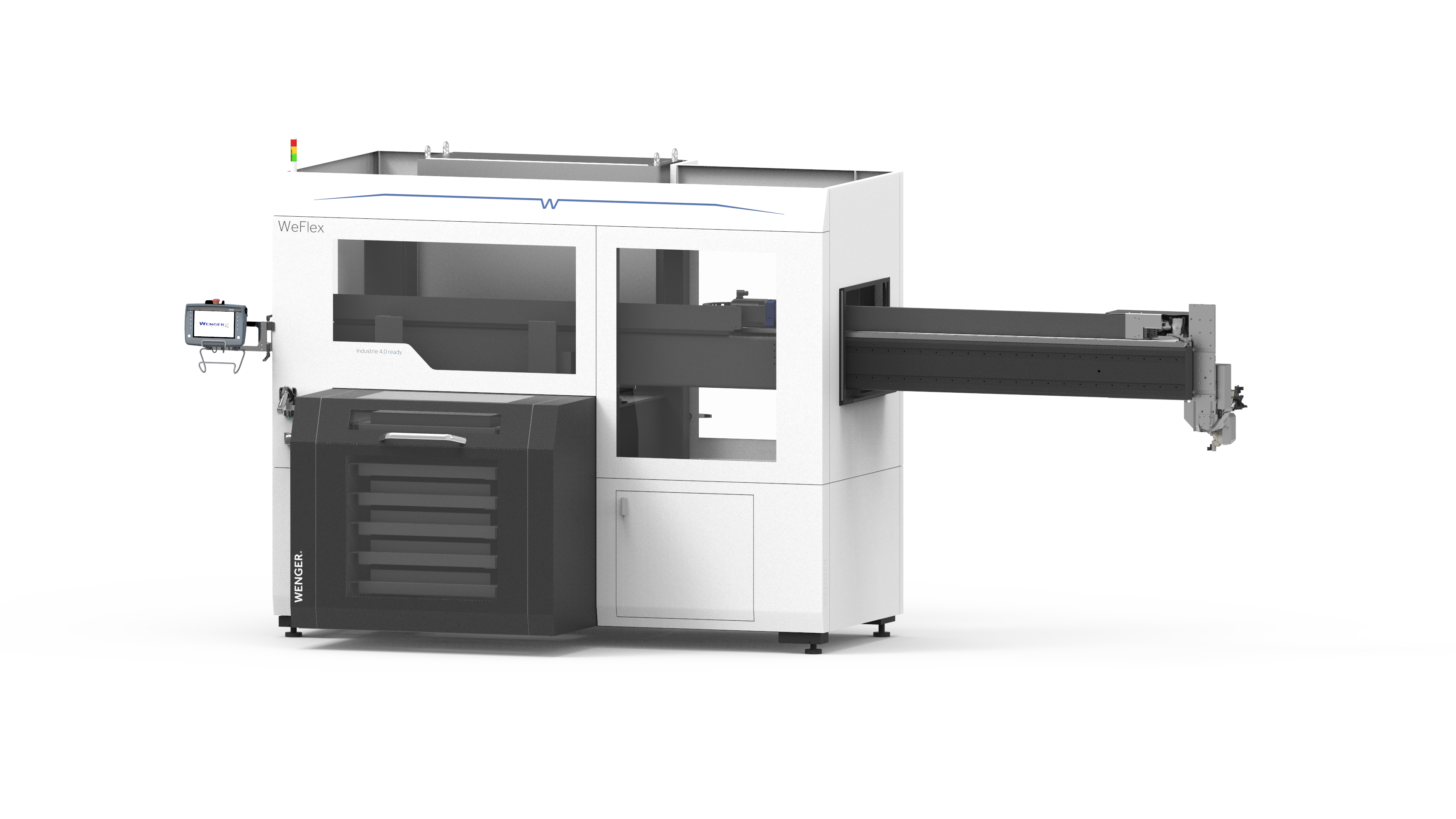

Technical data:

| WeFlex 600 | WeFlex 1000 | |

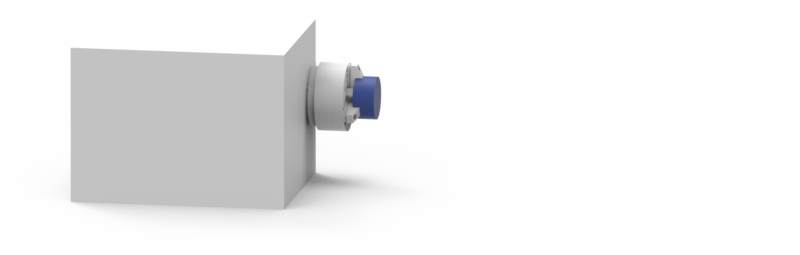

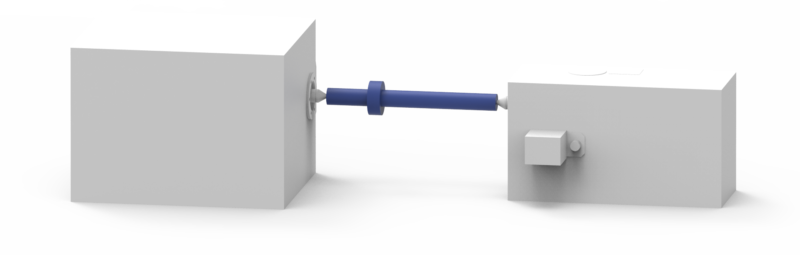

| Suitable for workpieces which are clamped in the chuck in the machine. |  |

|

| Suitable for workpieces which are clamped between the centres in the machine. |  |

|

| Number of pallet storage spaces: | 9 + 1x SPC/NOK | 9 + 1x SPC/NOK |

| Autonomy example chuck part Ø 80 L80: | 216 pcs | 300 pcs |

| Autonomy example shaft part Ø40 L170: | 96 pcs | 192 pcs |

| Pallet size (inside dimension): | 400x600mm | 400x1000mm |

| Max. dimension chuck part: | Ø260 L100 (up to 5 kg) | Ø260 L100 (up to 5 kg) |

| Max. shaft part dimension: *with geometry check possibly up to Ø260 possible |

Ø100* L600 (up to 15 kg) | Ø100* L1000 (up to15 kg) |

| Traversing speeds: | bis 4m/s | bis 4m/s |

| Foot print: | 2820x2020mm | 3160x2300mm |

| Height: | 2300mm | 2300mm |

| Weight: | ca. 2.5t | ca. 3t |

| Air pressure: Air consumption: Voltage: Backup fuse: max. power consumption: |

6bar 50l/min 3×400 VAC 25A 5kW |

6bar 50l/min 3×400 VAC 25A 5kW |

Further information on YouTube

Network with us