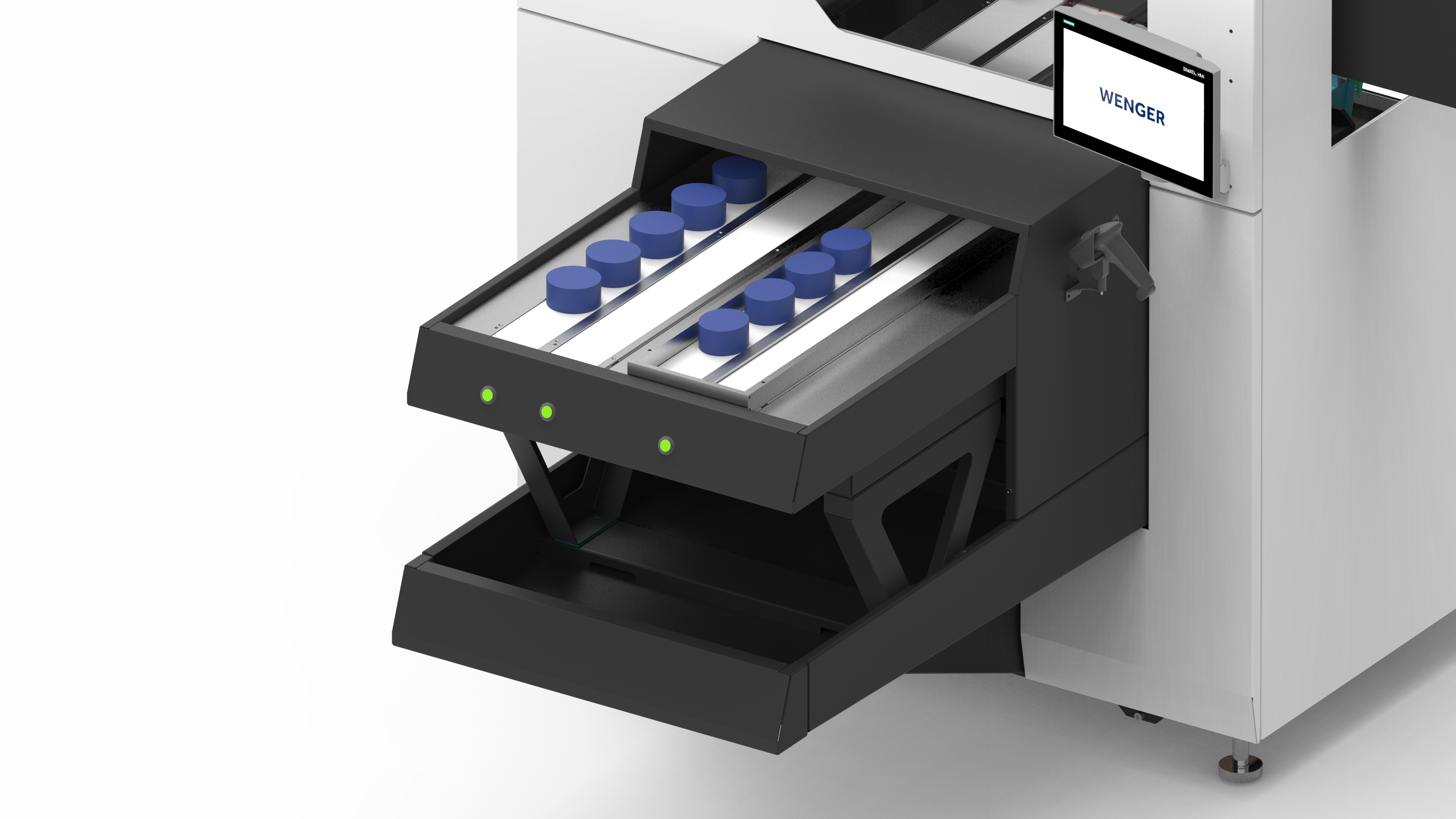

The WeFeed 100 belt cell was developed specifically for the automation of internal grinding machines.

The cell loads parts that are clamped in the chuck (chuck parts) up to Ø100mm and a length of up to 100mm.

The parts are fed via two belts. At the end position of the belt, the parts are fed to the grinding machine via linear gantry and changeable gripper head. The finished parts are placed on two output belts and led out of the cell for manual unloading.

Features:

- The belts do not need to be adjusted for different part diameters.

- Thanks to our quick-change gripper system, it is possible to change over to other part types within a very short time.

- The image-guided WENGER setup wizard supports programming and the changeover process.

Technical data:

| Suitable for workpieces which are clamped in the machine in the chuck. |  |

| Number of feeding belts à 1.8m | 2 |

| Autonomy example chuck part Ø 40 L80 | 90 pcs. |

| Max. dimension chuck part | Ø100 L100 (up to 5 kg) |

| Workpiece change time | approx. 6-10 s Without machine clamping times, depending on part weight |

| Traversing speeds | up to 4m/s |

| Foot print Height |

1600×2260 mm 2150 mm |

| Weight | ca. 1.5 t |

| Air pressure Air consumption Voltage Backup fuse Max. Power consumption |

6 bar 50 l/min 3×400 VAC 25 A 5 kW |

Network with us