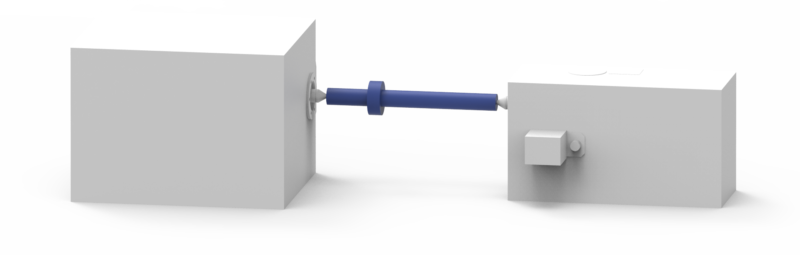

The WeChain 350 is specifically designed for the automation of shaft parts clamped between centres.

The cell loads shafts up to 350mm in length and 100mm in diameter.

Thanks to the quick adjustment of the feed cycle chain and the gripper jaws, the WeChain cell is particularly suitable for smaller series, whereby the system must be frequently changed over to new part types.

Features:

- The feed cycle chain can be adjusted to the part length within seconds using a handwheel. A second handwheel ensures the horizontal position of the parts on the chain, even with different diameters.

- The SPC parts are placed right-flush on the finished part conveyor. The NIO parts are dropped into a box behind the finished part conveyor.

- The image-guided WENGER set-up wizard supports the programme creation and the changeover process.

Technical data:

| Suitable for workpieces which are clamped between the centres in the machine. |  |

| Autonomy shaft parts up to Ø 34 outer diam. and Ø22 gripping diam. (each prism equipped) | 50 pcs. |

| Autonomy shaft parts from Ø22 gripping diam. (every 2nd prism fitted) | 25 pcs. |

| Max. dimension shaft part | Ø100 L350 (up to 15 kg) |

| Workpiece change time | approx. 6-10 s Without machine clamping times, depending on part weight |

| Travel speeds | up to 4m/s |

| Foot print Height |

1600×2260 mm 2150 mm |

| Weight | ca. 1.5 t |

| Air pressure Air consumption Voltage Backup fuse Max. Power consumption |

6 bar 50 l/min 3×400 VAC 25 A 5 kW |

Network with us