The WeBot 260 is characterised by the robot’s simple operation. Thanks to the intuitive user interface, no robot knowledge is necessary.

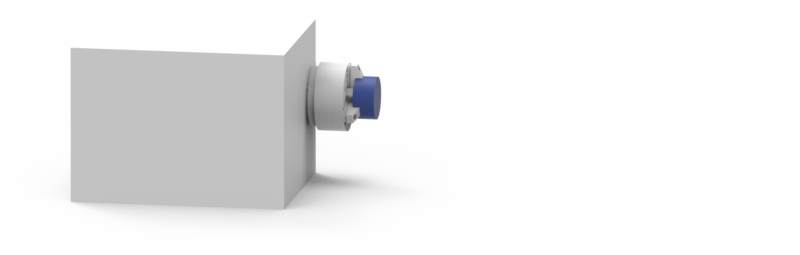

The machine tools are loaded laterally on the left or right, through an automatic hatch.

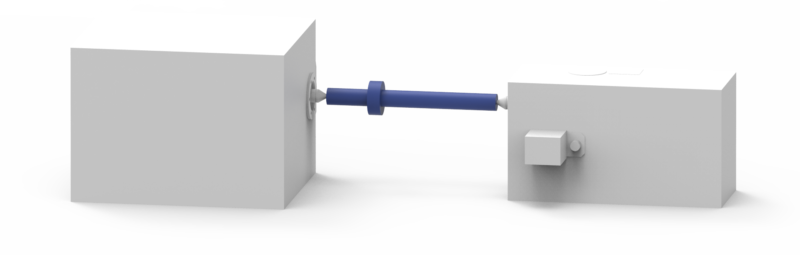

For two-machine operation, the robot can be placed on a linear axis.

The cell loads chuck parts up to Ø260mm and horizontal shaft parts up to approx. 300mm in length.

Features:

- Immediate access to all workpieces on the racks.

- The large workpiece storage enables autonomous working over a longer period of time.

- The layout on the 6 racks can be individually adapted to the part and batch sizes.

- The gripper fingers are equipped with a quick-change system as standard. Optionally, it is possible to change the gripper fingers completely automatically.

- The image-guided WENGER setup wizard supports programme setup as well as the changeover process.

- Integrated job management

Technical data:

| Suitable for workpieces (chuck parts) which are clamped in the machine in the chuck. |  |

| Suitable for workpieces (shaft parts) which are clamped between the centres in the machine. |  |

| Number of racks | 6 |

| Autonomy chuck parts up to L=100mm | |

| up to Ø30 | 648 pcs. |

| up to Ø38 | 324 pcs. |

| up to Ø80 | 162 pcs. |

| up to Ø130 | 72 pcs. |

| up to Ø260 | 24 pcs. |

| Autonomy shaft parts | on request |

| Max. part weight single mode | 7kg |

| Max. part weight alternating mode | 2.8kg |

| Workpiece change time | approx. 6-10 s Without machine clamping times, depending on part weight |

| Foot print | 1540×2485 mm |

| Height | 2130 mm |

| Weight | ca. 1.5 t |

| Air pressure Air consumption Voltage Backup fuse Max. Power consumption |

6 bar 50 l/min 3×400 VAC 25 A 5 kW |

Network with us